measurement of fluid film thickness|thickness measurement of thin films : makers This chapter describes the techniques for determining fluid film thickness and the relation of these determinations to the problem of fluid film failure. Methods of measuring film . Resultado da 14 de fev. de 2024 · BET+ is a premium online streaming service with over 2,000 hours of your favorite Black .

{plog:ftitle_list}

Resultado da Slots VIP. After years of debate, word is finally out that the local online casino in South Africa gambling market will be regulated in a matter of a couple of .

thin film thickness measurement techniques

compression test a pulled engine

thin film measurement techniques

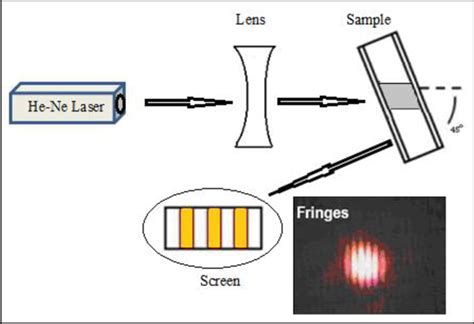

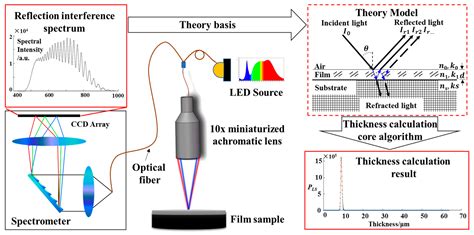

In the present study, an attempt is made to present a comprehensive literature review of the methods used so far for the measurement of liquid film thickness. Further, image processing technique is demonstrated as a potential candidate for the measurement of liquid . In this paper, we introduce a non-invasive optical method, named Paraxial Self-Reference Interferometry (PSRI) for thickness measurement of liquid films.3 Analytical Models on Liquid Film Thickness. Wilhem Nusselt in 1910 gave an expression for the film thickness of the vapor condensing on a vertical at plate as a function of thermal .

The liquid film velocity profile is the velocity distribution inside the liquid film adhered to the wall. Average film thickness is the thickness of liquid film averaged over the whole . This chapter describes the techniques for determining fluid film thickness and the relation of these determinations to the problem of fluid film failure. Methods of measuring film . Film thickness measurements. The methods of film thickness measurement in annular flow can be classified into two groups: methods involving contact with the fluid and .

Liquid Film Thickness Measurement: A Critical Review. April 2021. DOI: 10.1007/978-981-16-0159-0_10. In book: Advances in Fluid and Thermal Engineering (pp.101 . An oil-film thickness monitoring system capable of providing an early warning of lubrication failure in rolling element bearings has been developed. The system is used to measure the lubricant-film thickness in a conventional deep groove ball bearing (shaft diameter 80 mm , ball diameter 12.7 mm ).

compression test ac joint

The methods of film thickness measurement in annular flow can be classified into two groups: methods involving contact with the fluid and methods without contact. The methods with contact are: quick-closing valve method; methods based on measurement of conductance or conductance and capacitance of the film; electrical contact method. A ray-tracing-assisted (RTA) method for calibrating a fiber-optic thickness probe (FOTP) that enables the measurement of thickness in micrometers in wavy liquid-film flow is described herein. Measurement of the interface film thickness of mechanical seals has been of interest to researchers and industry for many years. This feature describes work to measure the liquid film using a novel ultrasonic approach with a view to developing a condition monitoring tool. . A promising technique for the monitoring of fluid film thickness is .CRAIC Film Thickness Measurement Tools. The 20/30 Film™ microspectrophotometer is a film thickness measurement system utilizing spectrophotometric measurements in either reflectance or transmission. Film thickness is recorded quickly .

The single bubble coalescence experiments used to validate the utility of hyperspectral imaging for thin film thickness measurements were performed using a modified Dynamic Fluid-Film . In these studies, emphasis was laid on film thickness measurement and effects of experimental parameters such as plate inclination angle and Reynolds number on film thickness. . The working fluid employed was the distilled water. It passes through a filter, a gear pump, a digital flowmeter, a water feeding reservoir and a liquid distributor . The thickness of the thin liquid film and its effects have always been a research hotspot in nuclear power applications and operating nuclear power plants, because the flow phenomenon of the liquid film is extremely common in multiphase flow research. Based on papers published in recent years, novel research progress on thin film thickness is reviewed .

Plots of (a) oil film and (b) water film thickness variation with time as the sealed fluid pressure is varied. Constant shaft speed of 1000 rpm.

Thus measurements of fluid film thickness by the methods described in the foregoing sections of this chapter cannot by themselves be used to predict lubrication failure; they must be employed in the full tribological context of the situation. Lubrication behavior in the presence of adsorbed "boundary" films and surface reaction products is .

Continuous measurement of the oil film thickness requires sensors to be attached to the test slipper. Bergada et al. [4], [5] constructed a slipper test rig which could measure the oil film thickness and pressure under the slipper simultaneously. Three displacement sensors at 120° intervals and four pressure sensors at 90° intervals were .

The tribological mechanism between the valve plate and the cylinder block in oil hydraulic axial piston pumps plays an important role on high power density. In this study, the fluid film thickness between the valve plate and the cylinder block was measured with discharge pressure and rotational speed by use of a gap sensor, and a slip ring system in the operating .

Film-Thickness Identification Method and Lubrication Characteristic Analysis of Rolling Bearings, National Center for Biotechnology Information, 2022. Oil Film Thickness – an overview, ScienceDirect Topics, n.d. Chapter 6 Measurement of Fluid Film Thickness and Detection of Fluid Film Failure, ScienceDirect, 2008.Measurement of fluid film thickness on the valve plate in oil hydraulic axial piston pumps (I)-bearing pad effects- Ki Kim, Jong; Jung, Jae-youn. KSME International Journal ; Seoul Vol. 17, Iss. 2, (Feb 2003): 246-253. Schubring and Shedd (2008) investigated liquid film thickness in horizontal annular air–water flow using the diffused light pattern reflected from the liquid surface. Working fluids were air and water. Glass tubes with inner diameters of 8.8 mm and 15.1 mm were used as test tubes.It was reported that the wave velocity of annular film was well correlated by the gas friction . Measurement of fluid film thickness on the valve plate in oil hydraulic axial piston pumps (I) - Bearing pad effects. February 2003; Journal of Mechanical Science and Technology 17(2):246-253;

Fig. 6 shows a typical measurement data of ethanol in D h = 1.0 mm channel at low capillary number, Ca = 0.011. In Fig. 6, a circular tube data δ tube is also shown for comparison. Liquid film thickness in a circular tube becomes nearly constant after the initial rapid decrease, which corresponds to the transition region between bubble nose and flat film region.

After 6 h testing, we get the continuous curve of liquid film thickness. X-axis represents time, Y-axis is film thickness (um). Fig. 13 is liquid film thickness curve in peak position in six hours when the liquid flows free, and Fig. 14 is liquid film thickness curve in hollow position in six hours when the liquid flows free. These measurements of the fluid film thickness and coefficient of friction are bulk average wafer scale measurements. Zoom In Zoom Out Reset image size Figure 9. Wafer downforce effects on fluid film thickness and coefficient of friction of a convex wafer polished with a 3.1 wt % fumed silica slurry solution [pad speed 0.47 m/s (60 rpm)]. . Condensation tests are carried out with HFE-7000 in two different test apparatuses, the first being composed of two counter-flow tube-in-tube heat exchangers separated by an adiabatic borosilicate glass tube for flow visualizations and liquid film thickness measurement, while the second consisting of a diabatic sapphire tube coupled with an .

Jae-Youn Jung, Jong-Ki Kim, 2003, “Measurement of Fluid Film Thickness on the Valve Plate in Oil Hydraulic Axial Piston Pumps . et al. Measurment of fluid film thickness on the valve plate in oil hydraulic axial piston pumps (Part II: Spherical design effects). J Mech Sci Technol 19, 655–663 . The starved inlet boundary conditions have been employed for oil film on each ring based upon experimental results obtained through scanning laser-induced-fluorescence oil film thickness measurement.

The liquid film falling around a horizontal tube is performed to explore the distribution characteristics of the film thickness. The liquid film thickness is measured by the conductance probe measurement method. The experimental results showed that the film thickness of the corrugated tube increases with the increasing of the film Reynolds .

Condensation tests are carried out with HFE-7000 in two different test apparatuses, the first being composed of two counter-flow tube-in-tube heat exchangers separated by an adiabatic borosilicate glass tube for flow visualizations and liquid film thickness measurement, while the second consisting of a diabatic sapphire tube coupled with an .

A unified model for large-scale thickness measurement of lubricating film based on ultrasonic lag phase slope. Ultrasonics 2023, 131, 106956. [Google Scholar] Wang, M.; Zheng, D.; Xu, Y. A new method for liquid film thickness measurement based on ultrasonic echo resonance technique in gas-liquid flow. Meas. J. Int. Meas.

The sonic velocity in a fluid is a function of the density of the fluid, which is dependent on temperature. Reid and Sherwood [102] . Film thickness measurements were evaluated from the fluorescent flow images by the threshold intensity pixel counting method. The intensity profile was checked at a typical flow cross section after subtracting . In the paper, a new capacitive sensor with a dielectric film coating was designed to measure the thickness of the liquid film on a flat surface. The measured me. . -contact capacitive experimental system was set up to achieve the measurement for conductive or non-conductive viscous fluid film thickness on a flat metal surface successfully .

Resultado da Home Uncensored. Announcement (May 1 2021): JavRave can now be access via javrave.club and javraveclub.com if you are blocked by ISP. .

measurement of fluid film thickness|thickness measurement of thin films